.jpg)

It mainly consists of switch components, wiring terminals, switch operating parts, and transmission parts. According to the mechanical mechanism of switch contact connection and disconnection, switch components can be classified into the following two types:

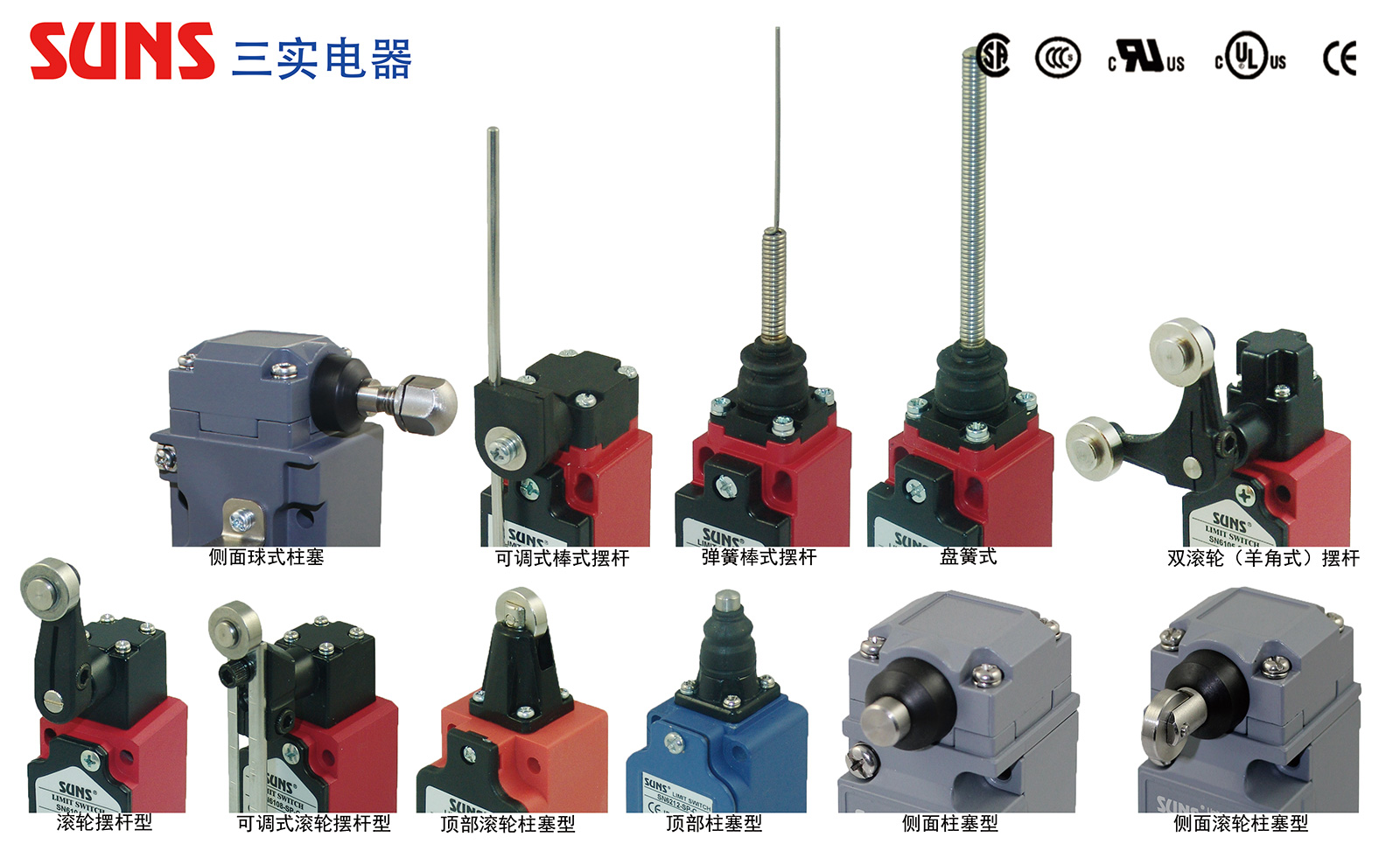

Limit switch

Slow motion switch: The switching time of the on and off actions of the switch is related to the operating speed of the switch. The faster the operating speed, the faster the switch is switched.

Quick action switch: The switching time between on and off of the switch is independent of the speed at which the switch is operated. As long as the switch operating component is operated to a certain position, the switch will switch between on and off. This process time is generally the time required for the spring to bounce, which is extremely short and constant.

·Simultaneous connection and disconnection of switch contacts

·When the contacts of the switch are separated by a certain distance, the equipment stops running. This should exclude the possibility of the contacts being reconnected due to vibration, which may cause the equipment to operate (switch hysteresis effect)

·When the operating speed is extremely slow

·When the DC current is disconnected, it is required that the current arcing disappear quickly

For the above applications, choose a quick action limit switch.

.png)

Selection elements of limit switches

1. Type of Drive Rod

2. Contact form

3. Action characteristics

4. Electric shock capacity

5. Operating environment

Action characteristics of limit switches

FP (Free Position): The position of the driving rod when no external force is applied

OP (Action Position): The position of the drive rod when an external force is applied to the switch contact, causing it to reverse from its free position

TTP (Total Travel Position): The position of the drive rod when it reaches the transmission stop position

RP (Return Position): Reduce the external force on the drive rod, so that the movable contact of the switch just reverses from the action position to the free position of the drive rod

OF (Action Force): The force that must be applied to the drive rod in order to move from the free position to the working position

RF (Response Force): The force that must be applied to the drive rod in order to move from the total travel position to the return position

TTF (Total Travel Force): The force required to travel from the free position to the total travel position on the drive rod

PT (pre stroke): The distance or angle of movement of the drive rod from the free position to the action position

OT (Over Travel): The distance or angle of movement of the drive rod from the action position to the total travel position

MD (Differential Travel): The distance or angle of movement of the driving rod from the action position to the return position

TT (total travel): The distance or angle of movement of the drive rod from the free position to the total travel position

.png)

.jpg)